Deskripsi

What is wafer butterfly valve?

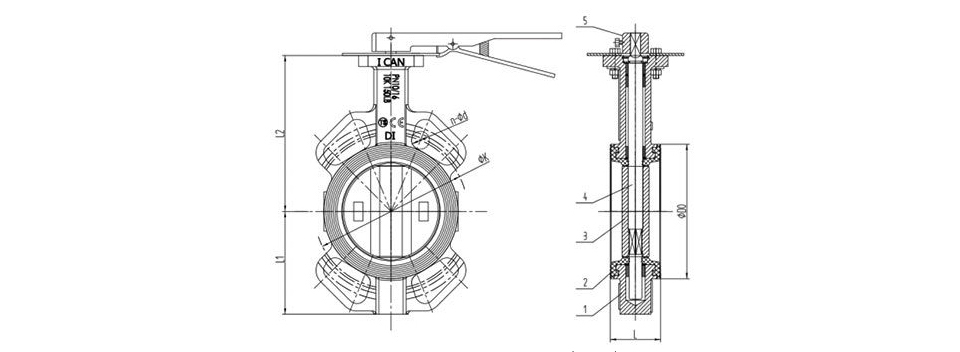

A wafer butterfly valve is a type of butterfly valve that is designed to be installed between two flanges using bolts or studs. This type of valve is called a “wafer” valve because it is very thin and has the same face-to-face dimensions as the flanges it is mounted between, making it more compact and lighter in weight than other types of valves.

Wafer butterfly valves consist of a disc that rotates around a shaft to control the flow of fluid in a pipeline. When the valve is closed, the disc is perpendicular to the flow, blocking the passage of fluid. When the valve is open, the disc rotates parallel to the flow, allowing fluid to pass through the valve.

Wafer butterfly valves are commonly used in limited space and weight applications, such as in HVAC systems, water treatment plants, and food and beverage processing industries. They are also used in applications requiring quick and easy installation and removal, such as in emergency shut-off systems.

| SIZE | A | B | C | L | ANSI 150B | DIN PN 10 | DIN PN 16 | JIS 10K | ISO 5211 | Top Flange | |||||||

| mm | in | øK | N-ød | øK | N-ød | øK | N-ød | øK | N-ød | øD | øD1 | N-øG | |||||

| 40 | 1.5″ | 67 | 141 | 32 | 33 | 98.5 | 4-ø16 | 110 | 4-ø18 | 110 | 4-ø18 | 105 | 4-ø19 | 65 | 50 | 4-ø8 | F05 |

| 50 | 2″ | 67 | 141 | 32 | 43 | 120.6 | 4-ø19 | 125 | 4-ø18 | 125 | 4-ø18 | 120 | 4-ø19 | 65 | 50 | 4-ø8 | F05 |

| 65 | 2½” | 75 | 151 | 32 | 46 | 139.7 | 4-ø19 | 145 | 4-ø18 | 145 | 4-ø18 | 140 | 4-ø19 | 65 | 50 | 4-ø8 | F05 |

| 80 | 3″ | 95 | 160 | 32 | 46 | 152.4 | 4-ø19 | 160 | 8-ø18 | 160 | 8-ø18 | 150 | 8-ø19 | 65 | 50 | 4-ø8 | F05 |

| 100 | 4″ | 111 | 180 | 32 | 52 | 190.5 | 8-ø19 | 180 | 8-ø18 | 180 | 8-ø18 | 175 | 8-ø19 | 90 | 70 | 4-ø10 | F07 |

| 125 | 5″ | 129 | 193 | 32 | 56 | 215.9 | 8-ø22.4 | 210 | 8-ø18 | 210 | 8-ø18 | 210 | 8-ø23 | 90 | 70 | 4-ø10 | F07 |

| 150 | 6″ | 142 | 207 | 32 | 56 | 241.3 | 8-ø22.4 | 240 | 8-ø22 | 240 | 8-ø22 | 240 | 8-ø23 | 90 | 70 | 4-ø10 | F07 |

| 200 | 8″ | 170 | 240 | 45 | 60 | 298.4 | 8-ø22.4 | 295 | 8-ø22 | 295 | 12-ø22 | 290 | 12-ø23 | 125 | 102 | 4-ø12 | F10 |

| 250 | 10″ | 206 | 270 | 45 | 68 | 361.9 | 12-ø25.4 | 350 | 12-ø22 | 355 | 12-ø26 | 355 | 12-ø25 | 125 | 102 | 4-ø12 | F10 |

| 300 | 12″ | 238 | 316 | 45 | 78 | 431.8 | 12-ø25.4 | 400 | 12-ø22 | 410 | 12-ø26 | 400 | 16-ø25 | 125 | 102 | 4-ø12 | F10 |

| 350 | 14″ | 267 | 368 | 45 | 78 | 476.2 | 12-ø28.4 | 460 | 16-ø22 | 470 | 16-ø26 | 445 | 16-ø25 | 125 | 102 | 4-ø12 | F10 |

| 400 | 16″ | 298 | 400 | 51 | 86 | 539.7 | 16-ø28.4 | 515 | 12-ø26 | 525 | 16-ø30 | 510 | 16-ø27 | 175 | 140 | 4-ø18 | F14 |

| 450 | 18″ | 318 | 422 | 51 | 105 | 577.8 | 16-ø31.8 | 565 | 20-ø26 | 585 | 20-ø30 | 565 | 20-ø27 | 175 | 140 | 4-ø18 | F14 |

| 500 | 20″ | 349 | 479 | 57 | 130 | 635 | 20-ø31.8 | 620 | 20-ø26 | 650 | 20-ø33 | 620 | 20-ø27 | 175 | 140 | 4-ø18 | F14 |

| 600 | 24″ | 410 | 562 | 70 | 152 | 749.3 | 20-ø35.1 | 725 | 20-ø30 | 770 | 20-ø36 | 730 | 24-ø33 | 210 | 165 | 4-ø22 | F16 |

Quality Control Process